How To Apply Weather Stripping To Sliding Windows

Whether for your attic or your basement, choosing the correct materials and installing them properly ensures the finished chore lives up to your expectations. This section describes the types of insulations, house wrap materials (air barriers and vapour barriers) also as details nearly weatherstripping windows and doors.

Summary

- iii.i INSULATION

- iii.2 INSULATION VALUES TABLE

- iii.3 AIR Bulwark MATERIALS

- 3.4 VAPOUR BARRIER MATERIALS

3.ane INSULATION

To be constructive, insulation must resist oestrus menses, make full the infinite completely and evenly, be durable, and for some locations, withstand exposure to heat or moisture. Different materials may exist used at unlike locations in the firm envelope depending on the space available, ease of admission and other installation requirements.

In addition, consider the following:

- Is the textile available locally?

- Is it relatively easy to install, especially for practice-it-yourselfers?

- Is it the best buy for the space available (either loftier insulating value per dollar if you have a lot of open space, or high insulating value per thickness if space is restricted)?

- Can it conform to surface irregularities?

- Is it rigid plenty to provide back up for finished materials or resist pressures confronting its surfaces?

- Does whatever single type of insulation crave more accessory products than some other (e.g. burn protection, air and vapour barrier or framing)?

For proper application, material handling, safety equipment and protective clothing requirements, follow the manufacturer's instructions (see Function one.4, Health and condom considerations).

3.1.i Do your research

Once you take selected a product, go the facts about it and find out nearly proper installation techniques. Compare the advantages, limitations and intended use of different products.

Materials (or their packaging) may be marked indicating that they comply with Canadian production standards. If they exercise non, they may have an evaluation number issued past the Canadian Structure Materials Centre.Your local municipal office can tell you if certain products are acceptable for use in your municipality.

Manufacturers, suppliers and contractors should be able to provide y'all with information about products. They should likewise be able to advise you on any health and safe bug (such equally indoor air quality and fire condom) and what they will practice to reduce these risks.

Ask for a Material Rubber Data Sheet (MSDS) that lists the chancy ingredients, prophylactic information and emergency measures related to specific products. An MSDS is required for certain industrial and chemical products used in the workplace like paint, caulking, spray foam insulation and cleaners. An MSDS is not required for manufactured items (e.yard. insulation) or consumer products, but information technology may be available from the manufacturer or supplier.

Manufacturers and suppliers are responsible for making sure that the products they sell comply with Canadian legislation. If you are concerned about the safety of a particular production, find out if it is prohibited or regulated nether the Hazardous Products Human activity (the Human action), other relevant federal, provincial or territorial legislation, or municipal bylaws.

For example, as of the date of publication, one type of insulation product is prohibited and two others are regulated nether the Deed.

Prohibited

- Urea formaldehyde-based foam insulation (UFFI) foamed in place (prohibited in Canada in 1980): This includes insulation products that are available in the United States that are urea-formaldehyde based and are installed via a foaming procedure.

Regulated

- Cellulose fibre insulation (regulated in Canada in 1979): This normally used and constructive insulation textile must run into certain functioning standards with respect to flammability, amid other things.

- Asbestos: A product equanimous entirely of asbestos cannot be sold equally a consumer product. Asbestos products applied by spraying must accept asbestos fibres coated with a binder during spraying and cannot come loose after drying.

For more data well-nigh the Human activity and for description on these requirements, contact Health Canada's Consumer Production Safety Part. Visit the Planning energy efficiency renovations for your home section of our website for more information.

three.1.2 Cost of materials

By and large, the toll per RSI value is lower for loose fill or batt type materials than for rigid board or foam type insulations. Notwithstanding, the cost of the bones material is but one aspect. High fabric costs may be offset by lower installation costs or the installer's preference for a item insulation technique.

3.1.3 Thermal performance: How effective is that material?

Thermal resistance values (RSI and R) are listed in Table iii-1. This table as well provides average design specifications because values for unlike manufacturer'south products of the aforementioned class may vary.

3.1.iv If it sounds as well skillful to be truthful . . .

Some manufacturers may claim that an insulation product offers remarkable insulating value. Whatever production that is promoted as offering a long-term thermal resistance exceeding RSI ane.14/25 mm (R-6.v/in.) may exist making a claim that is not substantiated by industry-recognized tests to specific accustomed standards. As well, exist alert to whatever manufacturer's thermal performance claims that are based on building envelope systems (due east.g. whole wall or ceiling configurations) that are not identical to those configurations or conditions in which the product is being considered for use.

3.1.v Summary of insulation types

Effigy 3-one Insulating materials and safety gear.

Larger image

This section explains the post-obit insulation types:

- batt or coating

- loose make full

- cellulose fibre

- glass fibre

- mineral fibre (mineral wool or stone wool)

- rigid board

- expanded polystyren

- extruded polystyrene

- mineral fibre rigid lath

- polyurethane and polyisocyanurate boards

- spray cream

- airtight-cell polyurethane foam

- open up-cell polyurethane foam

- cementitious foam

- reflective bubble foil insulations and radiant barriers

Batt or coating insulation

Glass fibre and mineral fibre (slag or rock wool) batt or blanket insulation is relatively easy to install in accessible spaces such equally exposed wall cavities and some attics. This type of insulation does not settle, it conforms to slight surface irregularities, and it can be cut to fit. To gain the maximum insulating benefit, batts and blankets should completely fill the space they are fitted into and neither be compressed nor have gaps (peculiarly avoid compressing the edges).

Some products are available in non-combustible form. Cheque with the manufacturer to verify that the products are non-combustible. Safety equipment and protective wear are required during installation.

TECHNICAL Notation:

Glass and mineral fibre insulations are typically poor air sealing products. Sometimes these products are stuffed into cracks and gaps (at the header in the basement or effectually a window) in an endeavour to block air leakage. This practice is non effective. E'er air seal by using appropriate materials and techniques.

Loose-fill insulation

Loose-make full insulation is suitable for walls and floors and excellent in attics and enclosed spaces, such as roofs, where the space between the joists may be irregular or cluttered with obstacles. You tin employ it to elevation up existing insulation in attics and accessible enclosed wall cavities and to fill in cracks and small or uneven spaces. Information technology is non advisable for beneath-course awarding. Employ safety equipment and wear protective article of clothing during installation.

Condom Alert:

Never allow insulation materials to come into contact with a chimney or a combustion vent, an exposed recessed lighting fixture or old knob and tube wiring because these can pose a fire hazard. Run across Office one.4, Health and safety considerations.

Loose-fill insulation may be poured or blown into cavities. Pouring will generally require more than material than blowing to achieve a specified RSI value. Bank check the manufacturer'due south information on the quantity of fabric required to provide a specified RSI value.

Most loose-fill materials installed in walls volition settle after installation, creating gaps at the top of the cavities. There are different installation approaches for each type of fabric to lessen this effect.

Loose-fill up insulation options include cellulose fibre, drinking glass fibre and mineral fibre described as follows.

i) Cellulose fibre

Cellulose fibre is made from shredded newsprint treated with chemicals that resist burn and fungal growth and inhibit corrosion. Because of its small-scale particle size, it can fill any gaps around obstructions such as nails or electrical wires that are within cavities.

All the same, bravado cellulose fibre can create a lot of dust. Exist sure to make assart for settling.

Cellulose fibre offers limited additional air sealing when blown into cavities that already have insulation. All the same, it volition provide increased air sealing when blown into empty and restricted cavities at dense-pack levels, typically around 56 kilograms per cubic metre (kg/thou³) (3.5 pounds per cubic foot [lb./cu. ft.]).

To reduce settling, some companies offer a moisture-spray installation technique for their products for open wall cavities that may require a fabric cyberspace. Drying fourth dimension varies for the different types and brands of production. A trained and manufacturer-licensed technician typically performs the installation.

ii) Glass fibre

Loose-fill drinking glass fibre is a like material to glass fibre batts, but chopped up for blowing or pouring applications. Paw-poured glass fibre works all-time in open horizontal surfaces such as attics. Blown glass fibre can exist used in both horizontal and vertical applications.

At conventional application pressure, information technology may be difficult to install in cavities that are partially blocked by nails, framing, electric wiring, etc. At dumbo-pack levels (i.east. around xl kg/m3 [2.v lb./cu. ft.]), higher RSI (R) values are achieved and tin can ameliorate fill cavities that have restrictions. For walls, application density is usually two to two-and-a-half times the manufacturer'south recommended rate of application for horizontal surfaces. This higher density ensures better overall application and performance.

Some products are classified as not-flammable. Check the manufacturer's specifications for verification.

iii) Mineral fibre (mineral wool or rock wool)

Mineral fibre is treated with oil and binders to suppress dust, maintain shape and ease the blowing process. It is similar to glass fibre in appearance and texture. Mineral fibre is suitable for accessible attics and inaccessible areas such as wood-frame walls, roofs or floors. For walls, the density of awarding is usually two to two-and-a-half times the manufacturer's recommended charge per unit of awarding for horizontal surfaces.

Mineral fibre may exist acceptable for insulating effectually masonry chimneys as information technology will not support combustion. However, bank check with your local building inspector to learn what is accepted.

Rigid board insulation

Rigid board insulation (insulating boards) is currently manufactured from mineral fibre or foam plastic materials. These materials have a high insulating value per unit thickness although the cost per RSI value is greater than that for loose-fill or batt or blanket insulations.

Insulating boards are lightweight and piece of cake to cut and handle. Plumbing fixtures them into irregular spaces, however, tin be a wearisome process. Some boards are available with special coverings (due east.g. a burn down-resistant fabric) and their own system of attachment. Some lath materials tin can be ordered pre-cut to specific sizes for an boosted cost.

When installed on interior surfaces, all plastic-based rigid board insulation must be covered with a burn down-resistant textile – typically xiii-mm (i/2-in.) drywall – that is mechanically fastened to the building construction. Plastic boards must be protected from prolonged exposure to sunlight, solvents and some sealants. Be certain to ask your supplier for a compatible sealant.

Rigid lath insulation options include expanded polystyrene, extruded polystyrene, mineral fibre rigid lath and polyurethane and polyisocyanurate plastic boards described as follows.

i) Expanded polystyrene

Expanded polystyrene (EPS), oftentimes called bead board, is made by using pressurized steam to aggrandize and course polystyrene beads into rigid foam plastic boards. High and low-density products are manufactured using steam every bit the bravado agent. Loftier-density board is more moisture resistant and can be used on the exterior of foundation walls in dry, sandy soils.

ii) Extruded polystyrene

Extruded polystyrene (XPS) is a foam plastic board with fine, closed cells containing a mixture of air and non-ozone depleting refrigerant gases (fluorocarbons). If joints are sealed properly, it can perform as an air barrier and, at certain thicknesses, may perform as a vapour barrier. Low permeability means that it does not blot or pass on wet, making it suitable for beneath-form applications.

iii) Mineral fibre rigid board

Mineral fibre insulation, when compressed and held together with a flammable folder, forms semi-rigid lath stock. The fibres are aligned vertically so that any water that penetrates the surface volition run downwards, making it suitable as a drainage layer. High-density, semi-rigid mineral fibre board for residential use is designed for below-grade outside applications.

iv) Polyurethane and polyisocyanurate boards

Polyurethane and polyisocyanurate plastic boards are fabricated of closed cells containing not-ozone depleting refrigerant gases (fluorocarbons) instead of air. They commonly come up double-faced with foil or are sometimes bonded with an interior or exterior finishing material. These products must be protected from prolonged exposure to sunlight and water. If the seams are well sealed, they can act every bit an air and vapour barrier. Use is mostly limited to areas where a loftier RSI is desired and infinite is limited.

Spray-foam insulation

Spray-foam insulation is made of plastic resin (e.g. soy-based resins or resins fabricated from recycled plastic) and a goad, which is prepared and applied on the job site. Spray kits for this type of insulation are available to the consumer, merely employing a certified installer who is trained in the awarding of the specific product will ensure the best results. The liquid foam is sprayed directly onto the building surface or poured into enclosed cavities with a pump-driven applicator. The foam expands in place and sets in seconds.

In that location are two types of foam: low density and high density. When installed on interior surfaces, all plastic-based foam insulation must be covered with a burn down-resistant material – typically thirteen-mm (1/2-in.) drywall – that is mechanically fastened to the building. All foam plastics must exist protected from prolonged exposure to sunlight.

Options for spray-foam insulation include closed-cell polyurethane foam and open-cell polyurethane foam described every bit follows.

i) Closed-cell polyurethane foam

Airtight-cell polyurethane foam (also chosen high-density or two-pound foam) is sprayed onto surfaces in layers not more than than 50 mm (2 in.) thick at each pass (if greater thicknesses are desired), where it hardens in seconds. A 24-hr curing and off-gassing period is required before occupancy can resume. The foam can expand 28 to 35 times its initial volume and should not be used in enclosed cavities.

This product tin be used as an air barrier. When practical to a thickness of 50 mm (2 in.), it tin can sometimes act as a vapour barrier. It tin exist used beneath grade and it bonds well to clean cement and masonry where it besides makes a expert moisture bulwark. Though high-density foam is a premium, hard textured, multi-task product, it is not mostly used to completely fill cavities due to its high price.

TECHNICAL NOTE:

The RSI (R) value listed in Table 3-1 may be lower than that quoted by the vendor considering it takes into account the loss of the blowing gases over time and the recent changes that ban the utilize of ozone-depleting blowing agents.

2) Open-cell polyurethane foam

Open-cell polyurethane foam (likewise known as depression-density or half-pound foam) is made from a combination of isocyanurate resins and catalysts, resulting in an open-celled, spongy semiflexible material. With a very high expansion rate – upward to 100 times its initial volume – and its lower comparative toll, this product is more than effective than closed-cell foam for filling larger cavities. It can be used as an air bulwark but not a vapour barrier.

Cementitious foam insulation

Figure 3-two Foil-faced foam lath acts equally an air vapour barrier.

Larger epitome

Recently introduced into Canada, cementitious cream insulation is a non-plastic based non-flammable textile with a soft chalky texture.

When poured or injected into cavities by a trained installer, it has the consistency of shaving cream and may require some drying out fourth dimension. This insulation can be used equally an air barrier simply not a vapour barrier.

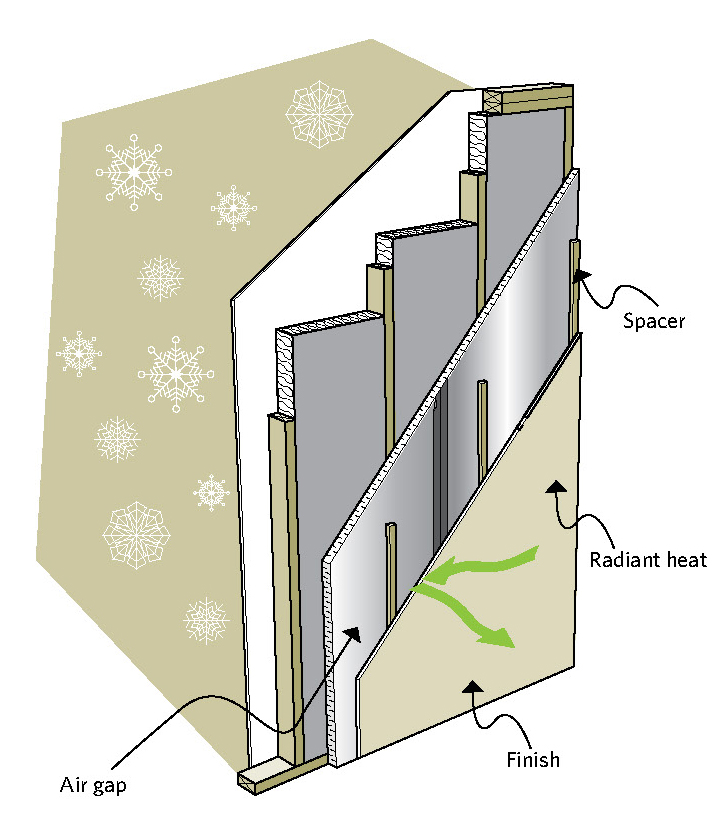

Cogitating bubble foil insulations and radiant barriers

Reflective chimera foil insulation is essentially a plastic bubble wrap canvass with a reflective foil layer and belongs to a course of insulation products known equally radiant foils. Reflective bubble foil insulations – and other radiant barrier products like paints and sheeting – are noted for their ability to reflect unwanted solar radiation in hot climates, when practical properly.

However, all of Canada is considered a common cold climate, and so these products do non perform as promoted. Though they are oftentimes marketed as offering very high insulating values, in that location is no specific standard for radiant insulation products, so be wary of posted testimonials and manufacturers' thermal performance claims.

Enquiry has shown that the insulation value of cogitating chimera foil insulations and radiant barriers can vary from RSI 0 (R-0) to RSI 0.62 (R-3.5) per thickness of material. The effective insulating value depends on the number of adjacent expressionless air spaces, layers of foil and where they are installed.

If the foil is laminated to rigid cream insulation, the total insulating value is obtained by adding the RSI of the foam insulation to the RSI of the dead air space and the foil. If there is no air space or clear bubble layer, the RSI value of the film is zippo.

3.ii INSULATION VALUES TABLE

This table lists the thermal resistance ranges and the accustomed design specification values or averages of insulation materials, including older and less common materials that you may find in a house.

| Material | Ranges RSI/25.4mm(R/in.) | Design spec or boilerplate RSI/25.4mm(R/in.) |

|---|---|---|

| Polyurethane airtight-cell spray foam | 0.97 to one.xiv (R-5.5 to 6.5) | one.06 (R-6) |

| Polyurethane board | 0.97 to 1.2 (R-5.5 to six.viii) | i.06 (R-6) |

| Extruded polystyrene board (XPS) | 0.88 (R-5) | 0.88 (R-5) |

| Polyisocyanurate spray foam | 0.85 to one.46 (R-4.8 to 8.3) | 0.88 (R-5) |

| Loftier-density glass fibre lath | 0.63 to 0.88 (R-iii.vi to 5) | 0.vii (R-4) |

| Expanded polystyrene board – Type I (EPS) | 0.67 (R-three.8) | 0.67 (R-iii.8) |

| Expanded polystyrene board – Type Il (EPS) | 0.vii to 0.77 (R-four to 4.4) | 0.vii (R-4) |

| Glass fibre roof board | 0.67 (R-3.eight) | 0.67 (R-3.8) |

| Cementitious foam | 0.69 (R-iii.9) | 0.69 (R-three.ix) |

| Cotton fiber fibre batt | 0.67 (R-3.viii) | 0.67 (R-iii.eight) |

| Cork | 0.65 to 0.67 (R-3.seven to 3.8) | 0.65 (R-three.7) |

| Polyurethane open up-prison cell spray foam | 0.63 to 0.67 (R-three.6 to iii.viii) | 0.63 (R-three.6) |

| Polyurethane open-jail cell foam, poured | 0.7 (R-four) | 0.7 (R-4) |

| Cellulose fibre, wet sprayed | 0.53 to 0.67 (R-3 to 3.eight) | 0.63 (R-iii.6) |

| Cellulose fibre, blown, settled thickness | 0.53 to 0.67 (R-3 to 3.eight) | 0.63 (R-three.6) |

| Mineral fibre batt | 0.53 to 0.7 (R-3 to 4) | 0.half-dozen (R-iii.4) |

| Wood fibre | 0.58 (R-3.three) | 0.58 (R-3.3) |

| Mineral fibre, loose make full, poured | 0.44 to 0.65 (R-2.5 to three.seven) | 0.58 (R-three.3) |

| Glass fibre batt | 0.55 to 0.76 (R-iii.1 to 4.three) | 0.56 (R-iii.2) |

| Glass fibre, loose fill, poured | 0.39 to 0.65 (R-ii.2 to three.seven) | 0.53 (R-3) |

| Mineral fibre, loose fill up, diddled | 0.51 to 0.56 (R-3 to 3.8) | 0.53 (R-3) |

| Drinking glass fibre, loose make full, blown | 0.48 to 0.63 (R-2.7 to iii.6) | 0.51 (R-ii.9) |

| Fibreboard (beaverboard) | 0.41 (R-2.3) | 0.41 (R-two.iii) |

| Mineral amass lath (Insulbrick) | 0.41 to 0.7 (R-two.3 to four) | 0.46 (R-2.6) |

| Forest shavings | 0.18 to 0.53 (R-1 to three) | 0.42 (R-2.4) |

| Vermiculite* | 0.37 to 0.41 (R-2.1 to 2.3) | 0.38 (R-2.2) |

| Compressed straw board | 0.35 (R-2.0) | 0.35 (R-two.0) |

| Eel grass (seaweed) batt | 0.53 (R-3) | 0.53 (R-3) |

| Cedar logs | 0.18 (R-1) | 0.18 (R-i) |

| Softwood logs (other than cedar) | 0.18 to 0.25 (R-1 to 1.4) | 0.22 (R-one.25) |

| Hardwood logs | 0.12 (R-0.7) | 0.22 (R-1.25) |

| Straw bale | 0.23 to 0.28 (R-1.3 to one.6) | 0.26 (R-1.45) |

| Radiant foil insulation | See Radiant foils | |

* See the vermiculite health and rubber alarm in Part one.4, Wellness and safety considerations.

iii.three AIR BARRIER MATERIALS

The main purpose of an air barrier organisation is to protect the edifice structure and the insulation from moisture damage. Information technology must resist air movement; be continuous, completely surrounding the envelope of the business firm; exist properly supported by rigid surfaces on both the interior and outside (to prevent movement in high winds); and exist strong and durable. Attention to particular during installation is disquisitional for good operation.

Various materials throughout the envelope act as an air barrier. Large-surface building materials such every bit drywall, baseboards or structural members and windows and doorframes are incorporated into the air barrier by sealing them to the adjoining materials. Caulking, tapes and gaskets are used for joints between materials that practice not move, and weatherstripping, for joints that practice move.

3.3.1 Choosing an air barrier textile

If the fabric that you lot are considering using offers resistance to airflow and is strong and durable, consider the following installation factors:

- Is information technology piece of cake to install without aid?

- If installed in a concealed location, volition it terminal the life of the building or will it exist accessible and hands repairable?

- Is it compatible with other materials in the system? Can information technology be successfully sealed to side by side materials?

- Is the choice of fabric appropriate for any other piece of work being done?

- Does it serve other functions such equally acting as insulation, a vapour barrier or part of a drainage airplane?

Sheet materials

i) Business firm wrap (typically made from a spun polyolefin plastic)

- is generally used to wrap the exterior of a business firm

- acts as a air current bulwark when installed on the outside; prevents current of air from reducing the nominal RSI value of insulation

- acts solely equally an air barrier; does not function equally a vapour bulwark

- can function as a drainage plane surface when the upper canvas overlaps the lower sheet and the flashings and all edges and penetrations are sealed with acoustical sealant or sheathing record

- application in wide sheets minimizes the number of seams required

- should be protected from extended exposure to sunlight

- when installed with stucco or embedded in stone veneers, requires an additional 5-mm (three/8-in.) gap for a drainage plane (utilize a drainage mat) to prevent the stucco from bonding to the house wrap

- should not come in direct contact with cedar because the oils in the wood tin cause deterioration in the production

ii) Polyethylene sheeting

- is ordinarily installed as a vapour barrier in the thickness of 0.15 mm (vi mil) considering it is more durable on the construction site

- should be labelled showing that it conforms to the Canadian General Standards Lath (CGSB) standard for polyethylene

- application in wide sheets minimizes the number of seams required

- should have the seams and edges supported on both sides to maintain the seal

- requires an appropriate sealant and overlapped joints

- functions as a vapour barrier. Should always be used on the interior or follow the ane/3 – 2/3 rule (see Part 1.4, Health and safety considerations). Follow local edifice codes for placement of a polyethylene vapour barrier.

TECHNICAL NOTE:

If the sheeting will exist exposed to sunlight over an extended period during renovations, utilise a UV-stabilized polyethylene.

iii) Polyamide sheeting

- is also known as Nylon-6 vapour retarder flick or smart barrier

- adapts its permeability to the conditions. In cold temperatures, information technology offers high resistance to vapour pressure; in warmer conditions, it becomes more permeable, assuasive the structure to dry out out.

- tin be installed as a vapour barrier or an air barrier

- should not exist used in indoor areas that accept high humidity such as an indoor spa or pool or a bathroom

iv) Rigid materials

Well-nigh solid building components including drywall, plaster, plywood, glass, wood, rigid foam insulation and poured concrete (not physical blocks) will human action as air barriers. Seal all seams between these materials with the appropriate caulking, weatherstripping, tape or gasket. For case, caulking can be used betwixt the baseboard and a wall as well as between the baseboard and the flooring, linking the air sealing qualities of 3 building components.

3.three.2 Sealants

Caulking seals joints betwixt building components. Most joints motility considering of changes in moisture and temperature in the building. Some materials can seal a larger articulation and accommodate more than articulation movement than others. Choose advisedly because there is wide variation among the same blazon of products produced under different brands. If possible, always select the premium product for long-term durability. Choosing the proper product and paying attention to the quality of application are crucial.

All sealants will require actress ventilation of the business firm after awarding to let the material cure. Typical curing time will be two or three days for interior applications. For application directions, come across Part 4.2, Caulking and other air sealing materials.

Materials labelled "for exterior apply but" may not be suitable for indoor applications because they may contain volatiles that may be chancy if inhaled in a confined space over an extended period. Read the manufacturer's literature advisedly.

The following factors limit the effectiveness of caulking:

- the flexibility and elasticity of the production. Some products can span a larger gap than others. Utilise a capitalist rod or foam rope in joints of 6 mm (i/4 in.) and larger before applying caulking to ensure an effective seal.

- its compatibility with the materials beingness joined. Read the manufacturer's literature carefully.

- its durability, paintability and curing fourth dimension. If the product will be exposed to sunlight, make sure it is appropriate for this condition.

- its ease of removal and reapplication. Some products tin can be used over previous applications while others cannot; some clean up easily with water, some require solvents, and some are very difficult to remove in one case cured.

Table 3-2 lists caulks and sealants bachelor at most building supply stores. Information technology is designed to aid you select the best production for each awarding. If possible, always select a premium production for long-term durability.

| Blazon | Bonds to | Application | Maximum joint | Comments |

|---|---|---|---|---|

| Acoustical sealant |

|

|

|

|

| Butyl safe caulk (constructed rubber sealant) |

|

|

|

|

| Silicone sealant caulk |

|

|

|

|

| Polysulphide caulk(synthetic rubber sealant) |

|

|

|

|

| Polyurethane caulk (urethane) |

|

|

|

|

| Acrylic latex caulk |

|

|

|

|

| Acrylic latex with silicone caulk |

|

|

|

|

| Elastomeric latex sealant |

|

|

|

|

| Urethane cream sealant (low, medium and high expansion types) |

|

|

|

|

| Latex cream sealant |

|

|

|

|

| Loftier-temperature stove or muffler cements and non-combustible sealants |

|

|

|

|

TECHNICAL NOTE:

Be mindful when using caulks and sealants. Urethane foams are impossible to remove one time cured, other products are flammable. Read manufacturers' literature and accept proper precautions during installations (article of clothing gloves, etc.).

three.iii.3 Gaskets

Gaskets are used to seal joints where caulking may not be appropriate. Table 3-three describes the most common types of gasket materials and where each blazon works all-time.

Tabular array 3-iii Gaskets

| Type | Application | Installation | Comments |

|---|---|---|---|

| Sill plate gasket (polyethylene cream strips) |

|

|

|

| Foam backer rod (closed-cell compressible foam rope) |

|

|

|

| Electric outlet and lighting fixture gaskets (pre-cutting) |

|

|

|

| Neoprene and elastomeric gaskets |

|

|

|

iii.3.4 Weatherstripping

Weatherstripping is used to cake air leakage effectually doors and the operable parts of windows. Weatherstripping comes in a multifariousness of shapes: flat strip, tube or Five (i.due east. V-strips), and can be designed to work under pinch or by sliding along the joint. To be effective, the product must close the gap and not permit air to laissez passer. Some products get hard – and less effective – in cold atmospheric condition when you need them the most.

When choosing weatherstripping, consider the size of the gap to exist sealed and the immovability, ease of installation and finished appearance of the product. Look for products that are flexible and that leap back to their original shape chop-chop and easily. Avert products that make it difficult to operate the window or door. When replacing weatherstripping, bring a sample of the erstwhile material to the store with you to ensure that you purchase the correct product.

A wide range of products is bachelor in most building supply stores, including complete sealing kits. For the best quality weatherstripping, contact window and door manufacturers or installers.

Table 3-4 lists the major types of products.

Table iii-4 Weatherstripping

| Category | Application | Installation | Comments |

|---|---|---|---|

| Airtight-cell cream (with or without vinyl roofing) |

|

|

|

| Ribbed closed-cell rubber | every bit in a higher place |

|

|

| Tubular stripping textile | equally to a higher place |

|

|

| Category | Application | Installation | Comments |

|---|---|---|---|

| Spring vinyl |

|

use large format for wide gaps |

|

| Spring metal |

|

|

|

| Category | Application | Installation | Comments |

|---|---|---|---|

| Leap-loaded, self adjusting |

|

|

|

| Magnetic-strip systems |

|

|

|

| Category | Application | Installation | Comments |

|---|---|---|---|

| Door sweeps (attach to the door) |

|

|

|

| Door bottoms |

|

|

|

| Thresholds (adhere to the flooring or door frame beneath the door) |

|

|

|

| Category | Application | Installation | Comments |

|---|---|---|---|

| Duct tape |

|

|

|

| Sheathing tape (i.e. scarlet technical tape) |

|

|

|

| Electrical box air barriers |

|

|

|

| Mastic putty |

|

|

|

| Mastic latex sealant |

|

|

|

| Pot light covers (recessed light covers) |

|

|

|

iii.iv VAPOUR Bulwark MATERIALS

The vapour bulwark is an of import component of the house envelope because information technology provides the structure and insulation some protection from moisture damage. The vapour barrier must resist the catamenia of water vapour from the interior, be durable and be located on the warm side of the insulation. In some cases it may be function of the insulation or air barrier. It should be piece of cake to install and appropriate for other work beingness done on the home.

Install the vapour barrier to protect the entire surface areas of insulated walls, ceilings and floors. Give special attention to all penetrations, joints and junctions (e.1000. light fixtures, wall plugs, switches and window frames) and areas that receive high humidity such as bathrooms and kitchens.

Usually located on the warm side of the insulation, the vapour bulwark can also exist installed part way into the wall, provided that no more than one 3rd of the insulating value of the wall is on the warm side of the vapour barrier. (For information about the 1/3 – 2/iii rule, see Part 2.four, Control of wet menstruation.)

This amount of insulating value should exist reduced to one quarter or less in very common cold climates or in buildings with high moisture sources such as swimming pools. Like an air barrier, the vapour barrier can exist made of various materials, including existing edifice components such as plywood, OSB, paint or vinyl wallpaper. In most older homes, the layers of oil-based primer and paint can function every bit an adequate vapour barrier for walls and ceilings.

Vapour barrier performance

The effectiveness of a vapour barrier (also known as a vapour diffusion retarder) is measured in terms of its permeability (perm) rating. The lower the perm rating, the more than effective the moisture barrier volition be. Materials considered to be effective vapour barriers include polyethylene, aluminum foil, polamide film (smart barrier), oil-based and latex vapour barrier paints (varying by type and thickness, some types and thickness of insulation and even some vinyl wallpapers).

Relevant topics: Department 1: Introduction

Back: Section 2: How your firm works Next: Section 4: Comprehensive air leakage control

Source: https://www.nrcan.gc.ca/energy-efficiency/homes/make-your-home-more-energy-efficient/keeping-the-heat/chapter-3-materials/15633

Posted by: brittainseatomint.blogspot.com

0 Response to "How To Apply Weather Stripping To Sliding Windows"

Post a Comment